Let our team identify or engineer

the perfect solution for your application.

With decades of expertise and the industry’s widest portfolio of powder bed materials, ALM expands opportunities for additive manufacturing

ALM provides consulting services, helping clients match the right material to the right application. While ALM already boasts a wide array of materials, it recently announced a partnership with 3D Systems to add DuraForm® PAx to its lineup.

The need for new materials is on the rise. In Scupteo’s 2015 State of 3D Printing Report, respondents were asked which trends they thought would have the greatest impact on 3D printing. 21.5% said “materials.” Just four years later, Scupteo’s 2019 study asked, “what does the 3D printing industry need to grow?” Roughly 60% of the respondents said, “new materials.”

Much of this stems from additive manufacturing’s transformation, from prototyping to production. In fact, Scupteo’s 2021 survey noted that 73% of “power users” (those who use 3D printing in a professional context) are making end-use mechanical parts and 49% said they use it for “large series production.”

There are many benefits to 3D printing, including short-run economics, customization, and speed-to-market. When engineers utilize Design for Additive Manufacturing (DfAM) principles, they can also develop stronger, lighter weight parts that provide higher performance, and simplified components that require less assembly.

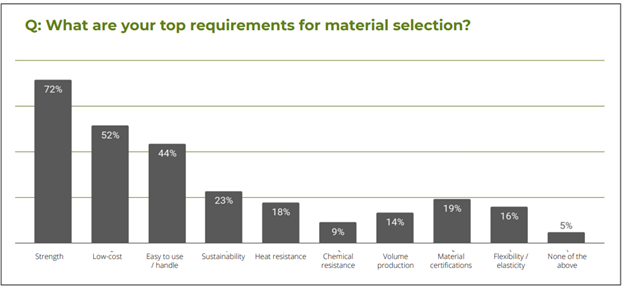

Success with 3D printing, especially end-use production, is dependent on material choice. In Scupteo’s 2021 study, “strength” was listed as the top requirement. But cost, sustainability and performance attributes like flexibility, heat and chemical resistance were also considered important.

Advanced Laser Materials (ALM) helps customers match the right material to the right application, focusing on developing and enhancing laser sintering materials for powder bed 3D printing applications. ALM takes a consultative approach with each client, following a four-phased approach that includes discovery, formulation, validation, and production.

During this process, technical requirements are gathered, materials are matched, and strenuous testing is conducted to ensure an optimal solution. When validated, ALM provides the approved material powder in the quantities required by each client and keeps a retain sample of every material batch to ensure quality control.

ALM works with users of many different types of powder bed systems and its catalog includes 35 different materials. But ALM is an EOS Company which offers 17 additional materials, creating a portfolio that includes 52 different polymer and composite materials. They offer a wide range of performance characteristics, including strength, flexibility, and heat and chemical resistance.

“We have long pursued a strategy of using our engineering expertise in formulating and producing high quality powders for Additive Manufacturing, providing the broadest portfolio of SLS materials on the market for all OEMs,” said Donnie Vanelli, president of ALM. “Now, our collaboration with 3D Systems expands the market’s material options opening up new applications and opportunities for the AM industry.”

Recently ALM announced a partnership with 3D Systems, adding DuraForm® PAx to its portfolio. This new highly recyclable nylon copolymer addresses many user needs, including lower-cost and better performance in a variety of industrial applications where parts require high impact and elongation.

DuraForm® PAx features properties similar to injection molding and can be used to manufacture tough, lightweight production-grade parts for many different industries including medical for orthotics and splints, aerospace and automotive for ducting, enclosures, fluid reservoirs, and even living hinge applications for consumer products.

To learn more about how ALM’s engineering expertise and wide product portfolio can help you achieve your vision for additive manufacturing, contact us today.

Let our team identify or engineer

the perfect solution for your application.