Let our team identify or engineer

the perfect solution for your application.

Plastic use is growing in many industries, but some like transportation and electronics have specialized needs, including fire safety. Additive manufacturing can provide many benefits, but fire-resistant materials are a core requirement. With ALM’s portfolio of fire-retardant materials, companies can unlock new applications and expand their use of 3D printing for production parts.

Polymer use is growing rapidly in many industries, including consumer products, electrical, automotive, aerospace, military, and transportation, among others. Engineering grade plastics are often chosen over metal and other materials because they enable lighter weight, better performing parts. But with the benefits also come limitations. Some thermoplastics are known to be more flammable than other materials, and to some degree this has limited their use, especially with additive manufacturing.

Over the years, there have been many catastrophic fires in cars, buses, trains, and planes. These fires often happen after a crash and can severely limit escape abilities. This risk led to a number of fire safety requirements for materials used in the manufacturing of vehicles, and the results have been lifesaving. For example, in 2005 an Air France AirBus A340 crashed at Toronto’s Pearson International Airport. Even though a fire broke out, all 300+ passengers and crew escaped. In 2013, a Boeing 777 crash landed at San Francisco International Airport and all but two survived. In both crashes, authorities cited flame-resistant materials as a key factor in preventing significant loss of life.

While fire-retardant materials are used with many different vehicle applications, the emphasis has been interior parts. These include everything from ceilings and floors, to dashboards, instrument panels, housings, air ducts, trim pieces, and more. Electronics are also a major application area and connectors, and switches play a crucial role in nearly every component. Besides the insulation benefits, plastics also enable engineers to improve the design of intricate electronic components. The materials used for these products are chosen for their electrical and mechanical properties, in addition to fire resistance.

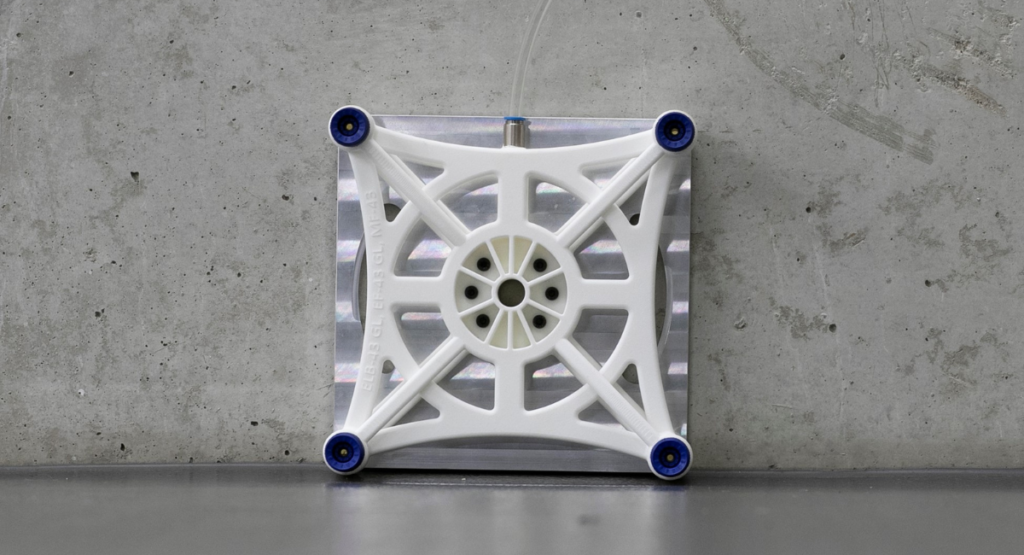

More recently, 3D printing has evolved to that point where it can more affordably produce batch parts. It also offers unique benefits that other technologies can’t. Because parts are built digitally, layer-by-layer, designers can incorporate shapes that can’t be made with injection molding and other plastic manufacturing processes.

For example, parts built with integrated ductwork can improve performance while reducing the cost of assembly. But they can only be produced additively.

Material choice is one of the big challenges for additive manufacturing. ALM is a wholly owned subsidiary of EOS and together we offer a portfolio of 45 different polymer materials for laser sintering. Several are specifically designed with fire safety in mind.

Parts manufactured with FR-106 exhibit superior mechanical properties, while maintaining high levels of fire retardancy. A fire-retardant Nylon 11, it is the only laser sintering material certified to pass the FAR 25.853 sixty second vertical burn requirement. Parts made with this material can withstand intense functional testing and are approved for end-use production applications.

PA-606-FR is the only commercially available fire-retardant Nylon 12 that meets the FAR 25.853 60 second burn specification. It enables accurate, repeatable part quality, offers a smooth surface finish and fine feature resolution.

HT-23 is a composite based on a PEKK resin with 23% carbon fiber compounded in. It offers isotropic properties, in addition to being chemical resistant and inherently flame retardant.

Developed in collaboration with BASF, Ultrasint® PA6 FR is an advanced engineering polymer powder containing a flame-retardant (FR) additive. It is Polyamide 6-based and offers halogen-free flame-retardance. Combining excellent mechanical and thermal performance with flammability requirements, this material is especially suitable for applications in the electronics and transportation sectors.

Together our unique portfolio of fire-retardant materials are helping customers unlock new applications that can leverage the many benefits of additive manufacturing. In some instances, though, material requirements are more stringent. In those cases, we take a consultative approach and follow a four-phase process including discovery, formulation, validation, and production, with the goal of developing a custom solution on behalf of our clients.

Let our team identify or engineer

the perfect solution for your application.